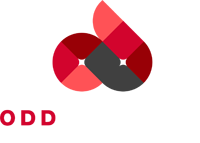

Embroidery has evolved into an art form that blends creativity with precision, and 3D puff embroidery takes it to another level. Mastering 3D puff embroidery tools is not just about skill; it’s also about having the right tools at your disposal. In this comprehensive guide, we’ll delve into the essential tools every embroidery enthusiast needs to elevate their craft to new heights.

First Steps: Introduction to Mastering 3D Puff Embroidery

Embarking on your journey to mastering 3D puff embroidery begins with understanding the tools of the trade. From digitizing software to specialized needles, each component plays a crucial role in bringing your designs to life with depth and texture.

Tools required for beginners

Initially, a beginner might feel overwhelmed by the array of tools available. However, to embark on this journey, one only needs the essentials. These include embroidery hoops, stabilizers, and high-quality threads. Investing in a variety of colors opens up endless possibilities for creative expression.

Dive into the world of creativity and precision with these indispensable tools for achieving stunning 3D puff embroidery designs.

Advanced 3D Puff Embroidery Tools: Elevate Your Craft with Precision

Once the basics are mastered, it’s time to explore the realm of advanced tools. These tools elevate craftsmanship, enabling artisans to create intricate designs with ease.

Introduction to advanced tools

Transitioning from beginner to expert requires a leap in tool sophistication. Advanced embroidery software empowers designers to unleash their creativity. Additionally, specialized heat guns and foam pads add depth to designs, enhancing their visual impact.

Their significance in achieving intricate designs

Moreover, these advanced tools are not mere luxuries but necessities. They streamline the embroidery process, allowing artisans to focus on honing their craft. With the right tools at their disposal, artisans can transform ordinary designs into extraordinary works of art.

Getting Started with the Right Tools: Choosing the Right Machine

To embark on the journey of mastering 3D puff embroidery, one must first invest in the right tools. At the heart of this endeavor lies the embroidery machine.

Initially, select a machine equipped with 3D puff capabilities. These specialized machines provide the necessary features and settings to achieve optimal results. Moreover, ensure the machine offers versatility, allowing for the exploration of various designs and textures.

Machine Maintenance

Embroidery machines are intricate devices that require regular upkeep to perform at their best. Neglecting maintenance can result in costly repairs and compromised quality.

importance of maintaining embroidery machines

Initially, artisans must understand the importance of machine maintenance. Routine cleaning and lubrication prolong the machine’s lifespan and ensure consistent performance.

Routine maintenance tips

Moreover, following manufacturer guidelines for maintenance is essential. Regularly inspecting and replacing worn parts prevents breakdowns and ensures uninterrupted workflow.

Thread Selection and Thread Management

Choosing the right threads is akin to selecting the perfect palette for a painting. Moreover, effective thread management is crucial for smooth embroidery operations.

Choosing the right threads

Initially, artisans must consider factors such as thread weight and composition. Polyester threads are a popular choice due to their durability and vibrant colors.

Tips for thread management

Moreover, proper thread tension and maintenance are essential for optimal embroidery results. Regularly cleaning machines and changing needles prevent thread breakage and ensure smooth stitching.

Puff Embroidery Foam

To achieve that distinctive 3D effect, you’ll need puff embroidery foam. This specialty foam adds dimension and texture to your designs, making them stand out. Choose foam of the appropriate thickness to achieve the desired level of puffiness.

Hooping Techniques and Accessories

Proper hooping techniques are fundamental to the success of any embroidery project. Moreover, the right accessories can make the difference between mediocrity and mastery.

Proper Hooping Methods for 3D Puff Embroidery

To achieve flawless results, mastering hooping techniques is imperative. Proper tension and alignment ensure that designs are stitched accurately and securely.

Essential hoops accessories

Additionally, accessories such as magnetic hoops and adhesive stabilizers enhance stability and efficiency. These accessories simplify the hooping process, saving time and minimizing errors.

Needles and Bobbins

Using the right needles and bobbins can make a world of difference in your embroidery work. Choose needles specifically designed for embroidery to prevent thread breakage and ensure smooth stitching. Additionally, regularly changing bobbins will help maintain consistent tension throughout your projects.

Software for Designing and Digitizing

In the digital age, software plays a crucial role in the embroidery process. Designing and digitizing software are essential tools for bringing imagination to life.

importance of digitizing software

Initially, converting designs into digital formats might seem daunting. However, digitizing software simplifies this process, allowing artisans to translate their vision into stitch-by-stitch instructions.

Top software recommendations

Furthermore, industry-leading software such as Wilcom and Hatch offer unparalleled versatility and precision. These programs provide a platform for experimentation, enabling artisans to push the boundaries of their creativity.

Stabilizers

Stabilizers play a crucial role in ensuring clean and precise embroidery stitches. They provide support to the fabric and prevent puckering or stretching during the embroidery process. Choose stabilizers appropriate for your fabric type and embroidery technique for professional-looking results.

Proper Lighting

Good lighting is essential for accurate color matching and detail work in embroidery. Ensure your workspace is well-lit with natural or daylight-balanced lighting to reduce eye strain and improve visibility. A well-lit workspace will allow you to focus on the intricate details of your embroidery projects.

Heat Press and Backing Material

Finally, pay attention to the finishing touches that elevate your embroidery from good to exceptional. A heat press serves as a crucial tool in securing the puff effect, ensuring that the design retains its dimensional quality over time.

Additionally, consider the choice of backing material. Opt for materials that provide stability and support without compromising the flexibility and texture of the embroidered piece.

Finishing Touches

The final stages of the embroidery process are just as crucial as the initial stitches. Attention to detail during finishing touches elevates the overall quality of the finished piece.

Trimming and cleaning embroidered pieces

Initially, trimming excess threads and removing stabilizers are essential steps in the finishing process. Moreover, cleaning embroidered pieces ensures they are free from debris and ready for display.

Quality control measures

Furthermore, conducting quality control checks guarantees that finished pieces meet the highest standards. Inspecting for loose threads and imperfections ensures customer satisfaction and enhances brand reputation.

Mastering the 3D Puff Embroidery Technique

Now that we have acquainted ourselves with the tools of the trade, it’s time to delve into the technique of 3D puff embroidery:

Design Selection

Choose a design that lends itself well to the 3D effect, with elements that can be elevated using puff foam.

Digitization

Convert your chosen design into a digital format compatible with embroidery machines. Pay attention to the details and ensure proper settings for the puff foam.

Hooping

Secure the fabric and puff foam in the embroidery hoop, ensuring they are taut and flat to prevent any wrinkles or distortions.

Stitching

Let the embroidery machine work its magic as it meticulously stitches the design, incorporating the puff foam where needed to create the desired raised effect.

Finishing Touches

Once the embroidery is complete, remove any excess puff foam and trim stray threads to reveal the masterpiece.

Leave A Comment